Fiber Breaks Faulty Connectors Sharp bends Bad Splices Fiber

Similar Faults located by VFL Fiber Visual Fault Detector

Whenever you need to install or troubleshoot fiber cables,Visual

Fault Locator (VFL)

is an easy and essential tool for quickly positioning the problem

areas.

As a fiber optic tester, VFL is used to trace optic fibers, check

fiber continuity and find fiber breaks,

damaged connectors, defective splices, tight bends in optical

cables.

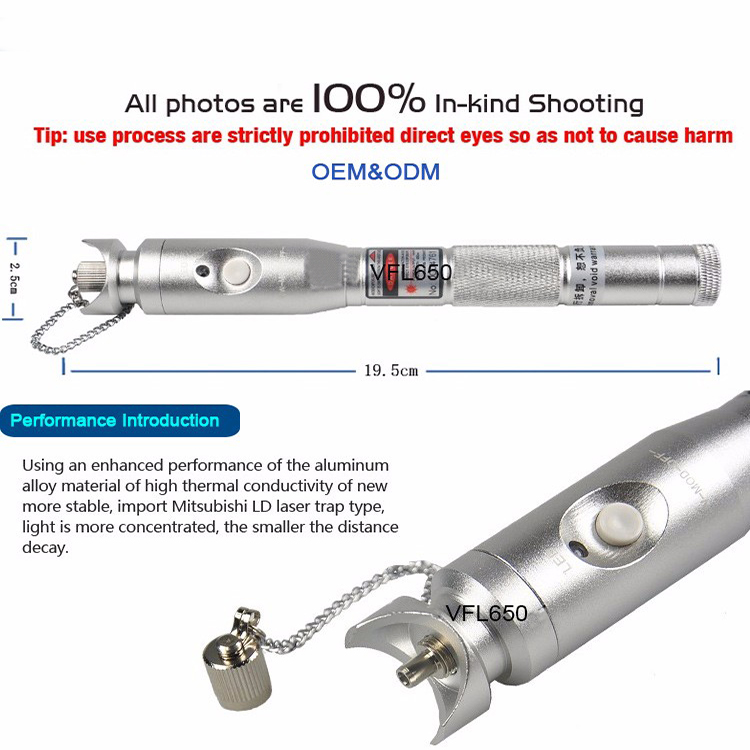

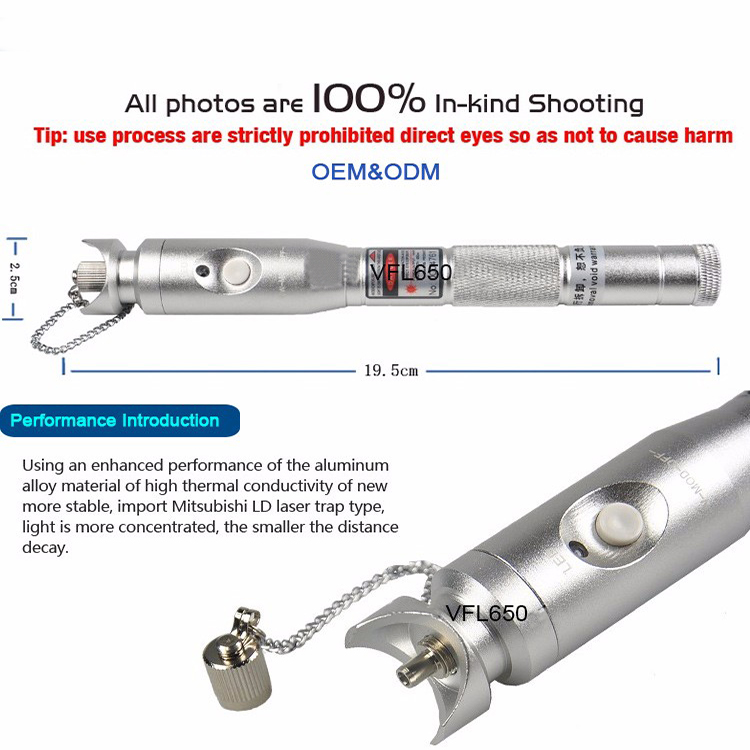

Two basic types of VFL are pen shape VFL and hand held VFL. Pen

shape VFL is very small with a pocket size to be carried anywhere.

Hand held VFL has a range of connector bulkheads styles from

universals to specific connector types.

How VFL Works?

The invisible light signals are typically transmitted at 1300 nm to

1650 nm wavelengths over fiber optic cables.

Different from the way thatOTDR (optical time-domain reflectometer)

locates the faults by measuring the time

of the incidence and the amplitude of the reflected pulses sent to

the fiber optic cable,

VFL uses powerful visible light at the wavelengths between 360 nm

to 670 nm to visually and quickly locate

the faults in the cables.

When the visible light leaks out at a certain point of optical

cable, it shows that the VFL has reached a fault.

It is also easy to see light leaking through the plastic cable

jackets under the right illumination of VFL.

Generally, a VFL can work at the distance between 2 km to 5 km.

| Model | HCW 650-2S |

| Central wavelength | 650nm±10nm (635nm is available on request) |

| Emitter type | FP-LD |

| Output power | 5mw 10MW 20MW 30MW |

| Laser Range | ≥5km |

| Optical connector | 2.5mm universal connector, for 1.25mm connectors, FC (Male)-LC.

(Female) convertor can be provided on request |

| Operating mode | Both CW and Pulse available |

| Pulse frequency | 2Hz to 3Hz / 9Hz |

| Power supply | 2AA alkaline batteries |

| Battery | LR6 AA alkaline battery |

| Operating temperature | -20°C to 60°C |

| Storage temperature | -40°C to 85°C |

| Dimension | 25 x 195mm |

| Weight | 165g (without battery) |

Using VFL is not a difficult task. Just follow the steps to know

the operation procedure:

Step one, remove the plastic connector covers from both ends of the

fiber cable.

- Step two, connect the VFL to one end of the fiber cable.

- Step three, press the tester button and observe whether light

emanates from the other end of the fiber. This gives a simple

indication of the continuity of the fiber link.

- Step four, repeat the above steps with other fiber cables to see if

visual light is leaking out from a faulty splice. This may

illustrate an easy way of carrying out visual fault locating on bad

splices or joints.

- Step five, disconnect all equipment, put the plastic covers back to

the connector ends and return everything to the state it was.

Notes:

- Point one, do not look directly into the VFL’s output.

- Point two, cover the VFL’s output with the dust cap when it is not

in use.

- Point three, VFL is not recommended to be used on dark colored or

armored cables.